GRAFINO

TACTICAL DRESS BOOT

Project Management | Client Liaison | User Research | Product Brief Creation | Concept Development | Tech Pack Creation | Concept Creation | Product Launch Presentation

VIP bodyguards need tactical personal protective equipment (PPE) that performs at the highest level while also hiding in plain sight to avoid becoming targets. Emerging brand Deo Juvante (DJV) aims to redefine VIP PPE by creating product that merges high performance with elevated design. To achieve this pairing of extremes, this sponsored team project leveraged a partnership between DJV and Bemis, a US-based no-sew bonding innovator, to create a full collection including formal attire, accessories, and two footwear designs. Through ethnographic research, our team discovered the insight that the protection officer’s highest priority is to escape danger as quickly as possible rather than engage. GRAFINO is a product concept for DJV footwear that blends into high fashion surroundings like the Oscars, while providing enhanced escapability through dramatic weight reduction, multi-terrain traction, and enhanced flexibility features hiding in plain sight.

The full sampling process was done individually with the guidance of concept creation staff. Materials on hand were selected for functionality and finish—not all colors are representative.

This cross-functional project was completed as a part of a 12-week PENSOLE product creation intensive, sponsored by DJV and Bemis. Our team consisted of two footwear designers, one apparel and accessories designer, and one color and materials designer. My roles during the project included team lead/project manager, client liaison, user researcher, footwear designer, and concept creator.

SUMMARY

Client Collaboration

OUTFIT THE MODERN KNIGHT

TO PERFORM HIS HIGHER PURPOSE

This project was designed as a collab between DJV, an emerging brand outfitting protection officers with personal protective gear, and Bemis, a no-sew technology manufacturer specializing in material bonding innovation.

User Research

“It’s crucial to blend in with what’s naturally occurring.”

“By far, any security detail in entertainment is the most challenging.”

“My biggest motivator is that it’s a natural calling for me.”

We conducted extensive research in the form of ethnographic interviews and live protection demonstrations in challenging scenarios that officers would face in the field. This research led to our focus on hiding performance features in plain sight.

HIDING IN PLAIN SIGHT

Inspiration

Our client brand, Deo Juvante, created its identity from the Crest of Monaco. It references the region’s history of being founded by warriors in disguise. The diamond motif, cross symbolism, and luxurious material qualities were all embedded in my final design.

The Transformers tagline is “more than meets the eye”. Their stealthy, faceted geometries and ability to disguise technology informed my overall design language, especially in creating the shape and structure of the tooling.

The Japanese puzzle box also informed my design language of clean, angular lines with precise edges and smooth, rounded surfaces. These elegant construction details also serve as protection for a precious valuable hidden inside.

CHallenges | Solutions

Traditional boots are stiff and overbuilt for the agility required in VIP protection. Snakeskin is an example of an alternative strategy with armor connected by a soft and conforming substrate. This material functionality informed the aesthetics and construction of the upper.

For VIP bodyguards who literally walk the red carpet, traditional dress shoes don’t provide any traction, leaving them flat-footed. A horseshoe-shaped sole can act as hidden traction that captures carpet pile in its central cavity to anchor the foot for quick changes in direction.

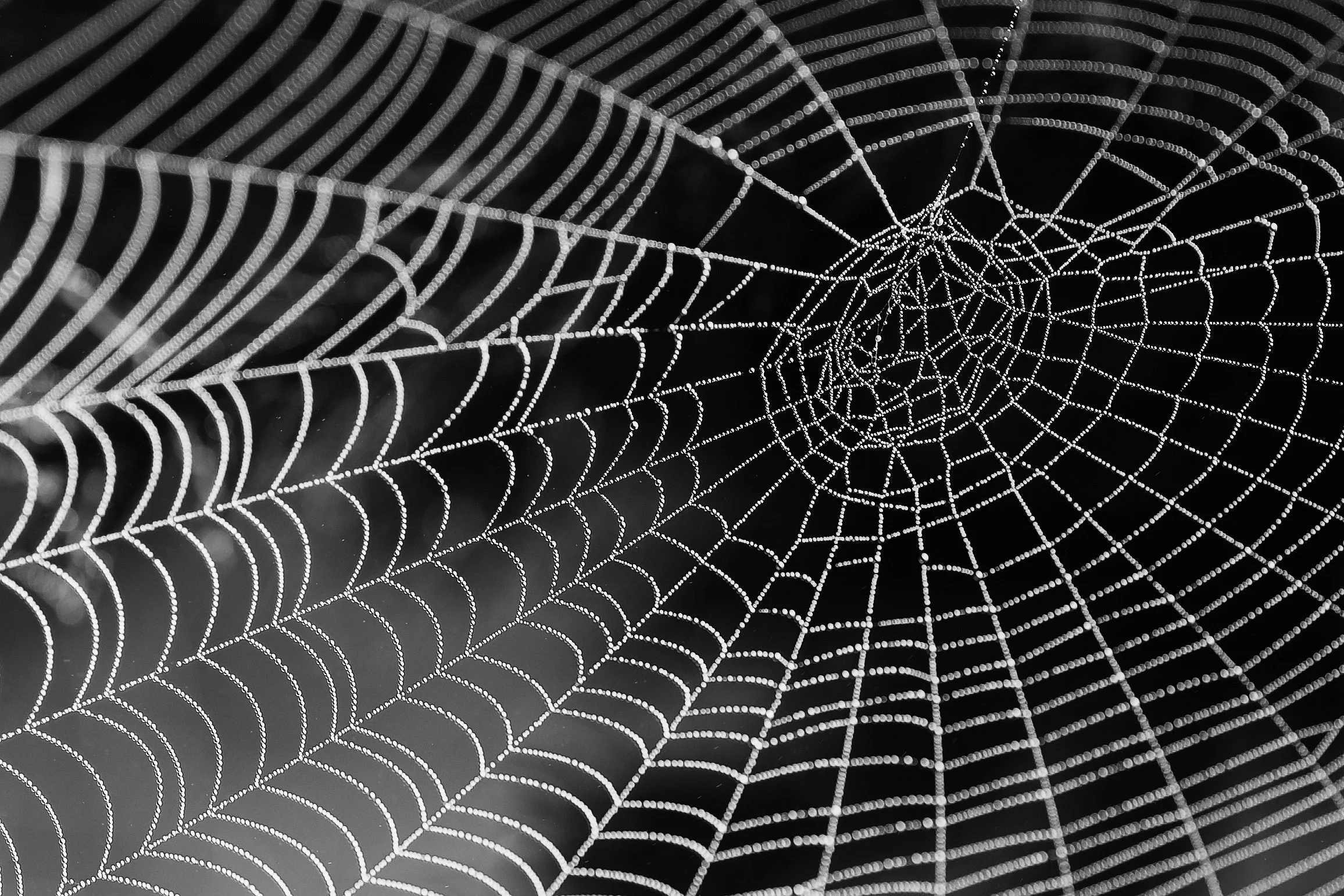

Both tactical boots and traditional dress boots are heavy with paneled leather and thick, dense soles. To reduce weight while still providing support and energy return, I looked to spiderwebs, which are optimized to evenly distribute and rebound against high forces.

ideation

FINAL DESIGN

The final design came together with many layers of symbolism and references to original inspirations, including a modified monk strap tying back to the Crest of Monaco, split diamond no-sew paneling for flexible structure like snakeskin, and a thin web component between upper and tooling in order to provide lightweight energy return.

Tech Pack

The tech pack was first drawn to scale and dimensioned completely by hand before digitizing in Illustrator. Tooling information was sent to Vibram to create silicone-molded parts for final sampling.

PullOvers

Multiple pattern trials were created—first by modifying an existing upper, then craft foam, and finally Ariaprene with hotmelt film. During the course of the sampling process, I also explored experimental prototyping methods like projection mapping to test color/material blocking and rapid prototyping to test tooling design.

Final Prototype

The final sample used an Ariaprene upper with Bemis paneling in multiple RPs, Clarino synthetic leather strap components, a Vibram custom-molded outsole, and a high-performance OrthoLite insole. Through the sample iteration process, I developed a workflow with an order of operations to maximize efficiency and minimize visual construction artifacts. This was especially important with so much no-sew construction and equipment limitations of a flat heat press and a small hand iron.

Packaging

In addition to designing and constructing my own shoe concept, I collaborated with my teammate to create an accessory bag for shoe storage, inspired by hunting rifle bags. The request for shoe storage was a curve ball thrown at the footwear teams while final samples were being built. My teammate and I were the only two footwear designers also acting as our own concept creators and still managed to complete both our own final samples as well as this shoe storage bag prototype within set deadlines.

Peripheral Mockups

Carbon Collection

Final Presentation

The Team

Bryant Chu - Footwear

Brian Gurevich - Color & Materials

Rachel Kao - Apparel & Accessories

Simone Dormann Pedersen - Footwear

Key learnings

Learn from users through demonstration—key insights like designing for agility instead of combat were identified through demonstration and physical references, which may have been overlooked through surface-level Q&A.

Prototype early with final design intent—tooling misalignment and multiple rounds of pattern adjustments could have been avoided by testing final materials and assembly earlier in the process. Material choice and pattern making are interdependent. I also resorted to a collar edge treatment on my final sample that could have been executed better/differently if it had been tested more in advance.

Opportunities for innovation can also be applied to the prototyping process—experimenting with projection mapping and craft foam mock-ups made me realize that the footwear sampling process itself seems like a rich area to explore alternative technologies and methods of make.

Develop a workflow, including buffer time for unexpected challenges—fine-tuning the order of operations was crucial to efficiently building a high quality final sample with limited resources. That efficiency and schedule flexibility I incorporated allowed for successful completion of an additional shoe storage deliverable that was a late request at the last stage of sampling.

Frequent feedback builds strong teams—the members of our team were open to feedback and constantly communicating with each other (3 of us were also coincidentally roommates), which led to great alignment and mutual support even through high pressure points in the process.